Zongyan Village, Zhouzhuang Town, Jiangyin City, Jiangsu Province, China

Stainless steel fittings

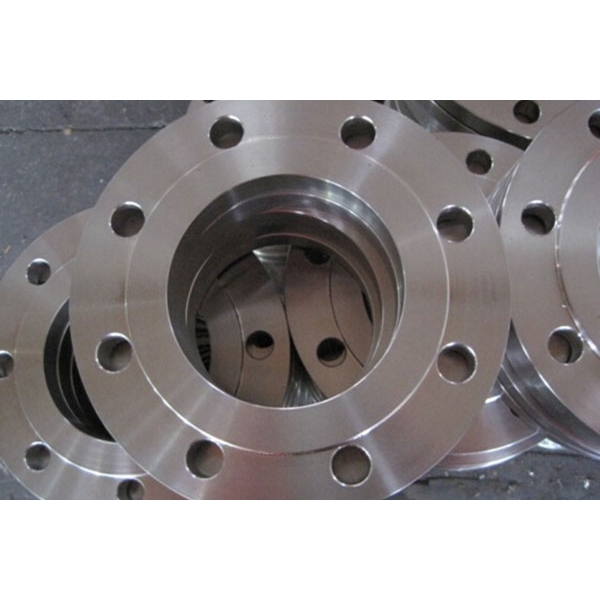

Stainless Steel Flange

- Order phone:+86-13306168278

- E-mail:dy@dystainless-steel.com

Detail

Flanges are the most common in pipeline engineering. Flanges are used in pairs and with matching flanges on valves. In pipeline engineering, flanges are mainly used for the connection of pipelines. In the pipelines that need to be connected, various flanges are installed. Wire flanges can be used for low-pressure pipelines, and welded flanges can be used for pressures above 4 kg. Add a gasket between the two flanges and fasten them with bolts. Different pressure flanges have different thicknesses and use different bolts.

When pumps and valves are connected to pipelines, parts of these equipment are also made into corresponding flange shapes, also known as flange connections. Any connecting parts that are bolted at the periphery of two planes and closed at the same time are generally called "flanges", such as the connection of ventilation ducts, such parts can be called "flange parts". But this connection is only a part of the equipment, such as the connection between the flange and the water pump, it is not easy to call the water pump "flange parts". Smaller ones, such as valves, can be called "flange parts".

A gasket is a ring made of a material that can produce plastic deformation and has a certain strength. Most of the gaskets are cut from non-metallic plates, or are made by professional factories according to the specified size, and their materials are asbestos rubber sheets, asbestos sheets, polyethylene sheets, etc.; Metal clad gaskets made of non-metallic materials such as wrapping; there is also a spiral wound gasket made of thin steel strips and asbestos strips. Ordinary rubber gaskets are suitable for occasions where the temperature is lower than 120°C; asbestos rubber gaskets are suitable for occasions where the temperature of water vapor is lower than 450°C, the temperature of oil is lower than 350°C, and the pressure is lower than 5MPa. The most commonly used medium is acid-resistant asbestos board. In high-pressure equipment and pipelines, lens-type or other-shaped metal gaskets made of copper, aluminum, 10-gauge steel, and stainless steel are used. The contact width between the high-pressure gasket and the sealing surface is very narrow (line contact), and the processing finish of the sealing surface and the gasket is high.

The low-pressure small diameter has a wire flange, and the high-pressure and low-pressure large diameter use welded flanges. The thickness of the flanges and the diameter and number of connecting bolts are different for different pressures.

When pumps and valves are connected to pipelines, parts of these equipment are also made into corresponding flange shapes, also known as flange connections. Any connecting parts that are bolted at the periphery of two planes and closed at the same time are generally called "flanges", such as the connection of ventilation ducts, such parts can be called "flange parts". But this connection is only a part of the equipment, such as the connection between the flange and the water pump, it is not easy to call the water pump "flange parts". Smaller ones, such as valves, can be called "flange parts".

A gasket is a ring made of a material that can produce plastic deformation and has a certain strength. Most of the gaskets are cut from non-metallic plates, or are made by professional factories according to the specified size, and their materials are asbestos rubber sheets, asbestos sheets, polyethylene sheets, etc.; Metal clad gaskets made of non-metallic materials such as wrapping; there is also a spiral wound gasket made of thin steel strips and asbestos strips. Ordinary rubber gaskets are suitable for occasions where the temperature is lower than 120°C; asbestos rubber gaskets are suitable for occasions where the temperature of water vapor is lower than 450°C, the temperature of oil is lower than 350°C, and the pressure is lower than 5MPa. The most commonly used medium is acid-resistant asbestos board. In high-pressure equipment and pipelines, lens-type or other-shaped metal gaskets made of copper, aluminum, 10-gauge steel, and stainless steel are used. The contact width between the high-pressure gasket and the sealing surface is very narrow (line contact), and the processing finish of the sealing surface and the gasket is high.

The low-pressure small diameter has a wire flange, and the high-pressure and low-pressure large diameter use welded flanges. The thickness of the flanges and the diameter and number of connecting bolts are different for different pressures.

If you have any questions or comments, you can leave us a message and we will reply to you as soon as possible